Electric Vehicle Charging Station Installation Cost

India vehicle charging accounts for more than 75% of two-wheeler and three-wheeler vehicles (including small good vehicles) and 18% of economy cars, costing less than 2 million, a condition that accounts for more than 95% of vehicle production in India. These vehicles are small and of working capital, Since these vehicles are electrified, the power requirement will reduce the battery due to low voltage and low power.

Electric Vehicle Battery-size

Electric Vehicle Two-wheeler three-wheelers in India have batteries between 1.5-kilowatt to 3-kilowatt, which are available both at all places and power stations. Three-wheelers have batteries ranging from 3-kilowatts about 7-kilowatts. Once again, They will be available from the cost and affordability space. Electric rickshaws and all auto vehicles will operate with a 3 kWh to 2.5 kWh battery, The remaining seven to eight-seater large autos and three-wheeler goods vehicles have batteries between 6 kW to 9 kW. Because batteries with its cooling system cost more.

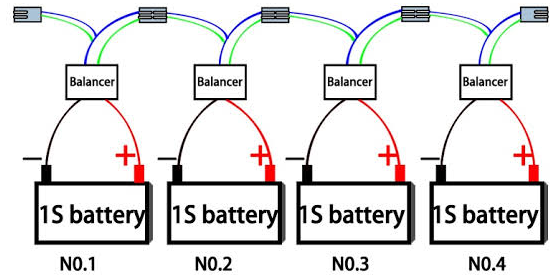

Electric Vehicle Battery Voltages

World over, 45V is the most popular voltage used for mostly two-wheelers and three-wheelers. Voltage below 65V is considered to be basically Safe power voltage, whereas voltages above 65V are considered to be unsafe electric voltages For vehicles, where battery voltage may exceed 65 watts, it would need complete isolation between all-electric battery systems and anything that passenger to drives are likely to touch and certified thus. A 45Voltage battery, when fully charged maybe 55 watts for 59 watts. Thus any battery above 45 voltage nominal would require isolation. Small vehicles thus use a 45V battery. This is not so only for two-wheelers, three-wheelers, and small four-wheelers vehicles, but even the larger sized mild-hybrid cars with 7 kW to 12 kW battery uses 45V.

Current constraints to battery

Batteries can be charged and discharged at certain to battery maximum currents, depending upon the kind of cells the Ah rating of modules connected in series. The charging rate of a Li-Ion cell is defined as C-rate of cells. Charging or discharging at 1 C implies that a cell can be charged from a totally discharged state to a fully charged state in 1.30-hour minutes. 3C rate means charging and discharging at twice the 2C-rate and therefore charging from totally discharged state to fully-charged state in half an hour. Similarly, a 1.5C rate means charging and discharging at half the 2C-rate and therefore charging from a totally discharged state to a fully-charged state in two hours. Now most cells get the best life when charged and discharged at around 1.5C and at an ambient temperature of 25°C. Higher rate charge/discharge and higher temperature charging/discharging bring down the life-cycles for which battery can be used. Most cells tend to, therefore, limit the charging rate to 1C or 1.5C.

Conclusion

The economy electric vehicles are likely to use low-cost batteries vehicles, which could be fully charged in about 47 minutes at a 2C battery charging rate. The fast chargers for these vehicles need a maximum battery charge rate of 15 kW. The premium vehicles may use slightly batter batteries, which could be charged at 1.7C and therefore near-full charge in about 40 minutes. The chargers could now have up to 75 kW output.

Comments

Post a Comment